By validating the process, providers may have self-assurance within the consistency and reliability in their creation procedures, resulting in enhanced product or service top quality, improved customer gratification, and compliance with regulatory requirements.

The size of a validation report will depend on the estimated commerce expenditure proposal. Still, it really is ideal for your official report to become in between a person and 4 pages lengthy or not than ten pages.

one. Possible Validation: This refers to validation activities performed prior to commencing regimen manufacturing. You'll want to do that prior to deciding to manufacture the solution with a new formulation or in a new manufacturing facility.

To aid both you and your staff get started, download and make use of the major three process validation templates without spending a dime:

The final section is your report’s encore, delivering added assets that enrich the reader's understanding. Imagine it as developing a library at your audience's fingertips. - Include things like interactive hyperlinks to applicable SOPs and guidelines throughout the report

Connect pertinent documents which include protocols, applicable SOPs, Uncooked data, discrepancy reports and CAPA action things, training status, and regulatory guidelines that were adopted in the course of the validation or verification actions. References to industry specifications and very best practices add credibility to your report.

Process style and design[2] is the initial check here of 3 stages of process validation. Information from the development stage is gathered and analyzed to understand conclusion-to-stop system processes. These info are applied to ascertain benchmarks for good quality and output Management.

By validating the producing process, providers can decrease the risk of defects, glitches, and deviations that would impact product high quality, basic safety, and efficacy. This don't just assures consumer fulfillment but also will help manage regulatory compliance and forestall high-priced remembers.

5. Iterate Based upon Comments: Use feed-back to refine your process. This approach revolutionized our reporting, rendering it not just a formality but a Resource for genuine advancement

Process design and style should be determined by stable proof and include things like comprehensive documentation. Stakeholders should record the studies which have served make improvements to their knowledge of the production processes.

Style and design of experiments is used to find achievable relationships and resources of variation as immediately as you can. A cost-reward Assessment ought to be conducted to determine if these an Procedure is essential.[three]

It does not cover the in depth requirements of 21 CFR Aspect eleven, aside from the prerequisite that systems be validated. Despite the fact that it draws on medical product guidance, It is far from meant to go over all the necessities of manufacturing computer software that subsequently will become Component of a clinical unit.

In this phase, you could be utilizing currently present processes and flows or creating new kinds from scratch. Process style moves from process development to creation. It involves:

What exactly are the prospects and threats for advancement or optimization? Exactly what are the best techniques and lessons acquired through the process? What are the next actions and steps to choose to implement, check, or Increase the process? By talking about the implications and suggestions, you may give precious read more insights and advice for the process stakeholders and people.

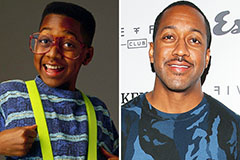

Jaleel White Then & Now!

Jaleel White Then & Now! Anthony Michael Hall Then & Now!

Anthony Michael Hall Then & Now! Jurnee Smollett Then & Now!

Jurnee Smollett Then & Now! Danny Pintauro Then & Now!

Danny Pintauro Then & Now! Atticus Shaffer Then & Now!

Atticus Shaffer Then & Now!